Picture this: You’re sitting at the helm of your operation with a crystal-clear view of every moving part, like a maestro conducting a perfect symphony. That’s what PPC software delivers. You get real-time visibility that lets you make power moves before your competitors even know what hit them. We’re talking about scheduling that’s not just months ahead but scary accurate, letting you pivot faster than a startup when market winds shift.

But here’s where it gets really interesting – the resource optimization. It lets companies slash their inventory costs by 30% or more just by implementing this system. We’re talking serious money flowing straight to your bottom line. And when it comes to scaling? This software is your growth accelerator, handling expansion like it’s child’s play.

Here’s what you should demand from your Production Planning and Control software:

1. Order Projections and Buyer Capacity Bookings

Your production planning software should enable manufacturers to analyze order projections and anticipate buyer capacity bookings. So, manufacturers have an understanding of the demands that are coming their way – buyer commitments and available capacity. It enables them to optimize production processes, prepare for upcoming orders, and reduce the risk of delays or overbooking to prevent last-minute surprises. Moreover, manufacturers will get enhanced productivity by preparing for future orders. This is especially important in the Mass Production Method and Process Manufacturing Method, where manufacturers deal with high-volume, repetitive processes.

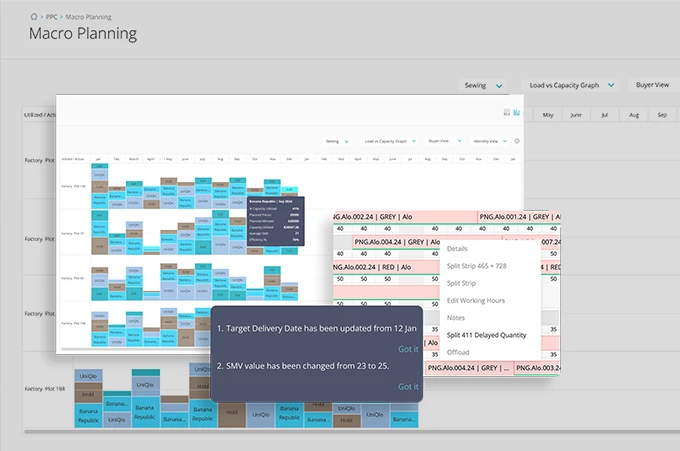

2. Capacity Utilization and Overbooking Insights

Real-time production capacity information provided by software helps manufacturers determine if orders will satisfy the designated time requirements. Through real-time insights, the software allows manufacturers to modify their production schedules and workflows, preventing expensive workflow disruptions.

3. Ex-Factory Date: The Ultimate Benchmark

Your Production Planning and Control software should align all production activities with the Ex-factory date. The ex-factory date is a critical benchmark that drives production schedules and shipment commitments. It will ensure on-time deliveries and maintain buyer satisfaction.

4. Production Efficiency and Data-Driven Decision-Making

The software should empower manufacturers to make informed, data-driven decisions with real-time insights into production timelines, capacity usage, and potential bottlenecks. Moreover, the software’s interactive visualizations should allow manufacturers to assess production processes and optimize workflows in order to minimize inefficiencies.

5. Seamless ERP Integration

The software should seamlessly integrate with existing Enterprise Resource Planning (ERP) systems, unlike other planning tools that require complex setups. It should fit within your existing ERP effortlessly. It eliminates the need for additional configuration and ensures a streamlined workflow across departments.

6. Scenario Analysis

Your Production Planning and Control software should enable the manufacturers to simulate various production scenarios and predict potential outcomes. Gaining insights into different possibilities helps manufacturers prepare for unexpected challenges, ensuring flexibility and resilience when faced with market fluctuations.

7. Material Requirements Planning (MRP)

The software should offer MRP functionality so manufacturers can effectively manage material procurement, avoid delays, and optimize inventory levels. This feature guarantees that materials are on hand when needed, improving production scheduling and reducing last-minute purchases.

8. Demand Forecasting

Your software should allow manufacturers to predict market trends and customer demand by analyzing historical data. The manufacturers will be able to make proactive decisions about production volumes and resource allocation, ensuring they meet demand without overproducing or understocking.

9. Order Processing Management

The Production Planning and Control software should streamline the order management workflow to ensure the smooth tracking of orders from initiation to delivery. It will help manufacturers minimize errors, ensure timely deliveries, and strengthen better customer service.