In today’s fast-paced, hyper-competitive fashion industry, garment businesses can’t afford to rely on outdated, manual processes. The right PPC software isn’t just a tool—it’s a game-changer. It’s the backbone of a lean, agile, and future-ready operation.

Here’s what forward-thinking garment businesses should prioritize when choosing PPC for manufacturing software, broken down into actionable insights:

1. Order Projections & Buyer Capacity Bookings

A key component of any PPC software is its ability to manage order projections and buyer capacity bookings. Your chosen software should help in keeping all the historical data organized to forecast demand. It’ll allow you to analyze how your capacity will be utilized in the future. Moreover, it should provide clear insights into buyer commitments and available capacity to prevent last-minute surprises.

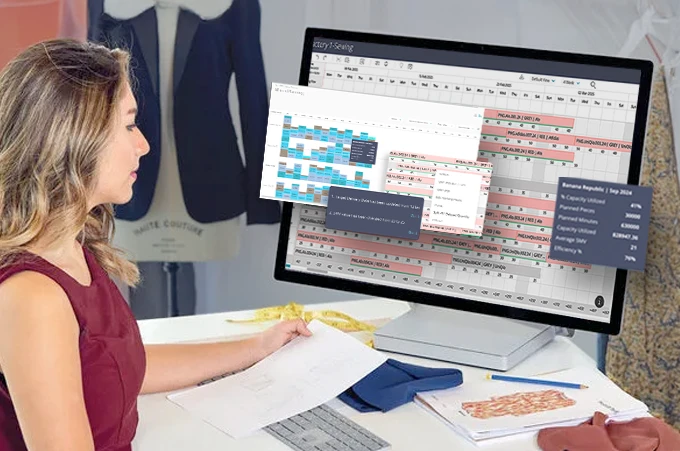

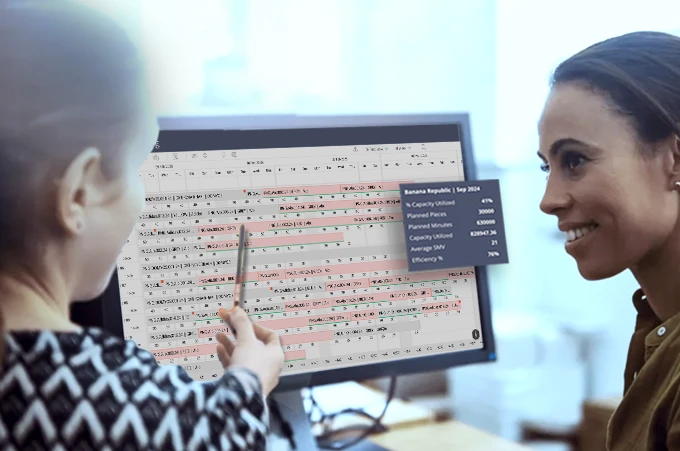

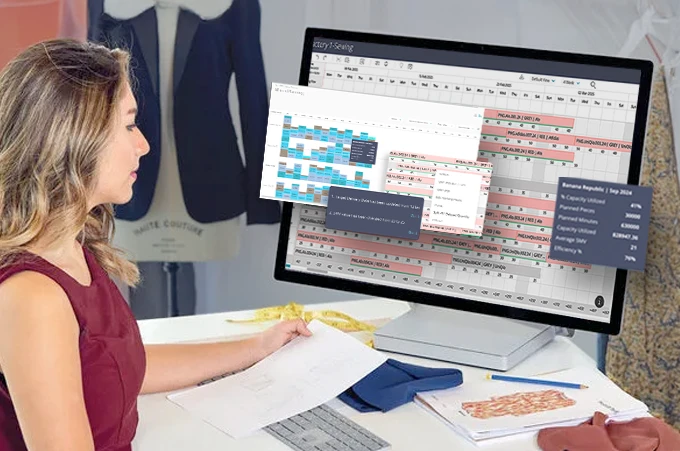

2. Capacity Utilization & Overbooking Insights

Real-time visibility into capacity utilization is essential for garment manufacturers. Therefore, ensure that your PPC software allows you to generate insights into whether an order can be completed within the allocated time slot or not. Additionally, it should highlight potential overbooking scenarios so manufacturers can take proactive steps and avoid delays and inefficiencies in the process.

3. Ex-Factory Date Management

The Ex-factory date is the cornerstone of the production timeline in the garment industry. Manufacturers have to keep track of all the processes for on-time deliveries and buyer satisfaction. Therefore, before choosing any PPC software, ensure that it has features like charts and graphs to let you track and synchronize production schedules. Your robust PPC software should help minimize delays and maximize reliability.

4. Real-Time Tracking & Monitoring

The PPC software you opt for your garment business should allow you to oversee every stage of production—from fabric cutting to stitching to finishing with its visualization tools. Moreover, it should include features such as Work-in-Progress (WIP) tracking, component traceability, RFID/barcode integration, comprehensive report generation, and live dashboards so you can get immediate insights into order statuses. Selecting such a PPC tool will help in identifying bottlenecks and delays before they become problems.

5. Seamless ERP Integration

Planning tools require complex integration with third-party ERPs. Therefore, the PPC software you pick should have a well-integrated Enterprise Resource Planning (ERP) system so all departments work in harmony. Moreover, it should integrate seamlessly with your existing systems across sales, production, inventory, and procurement for optimized workflows.

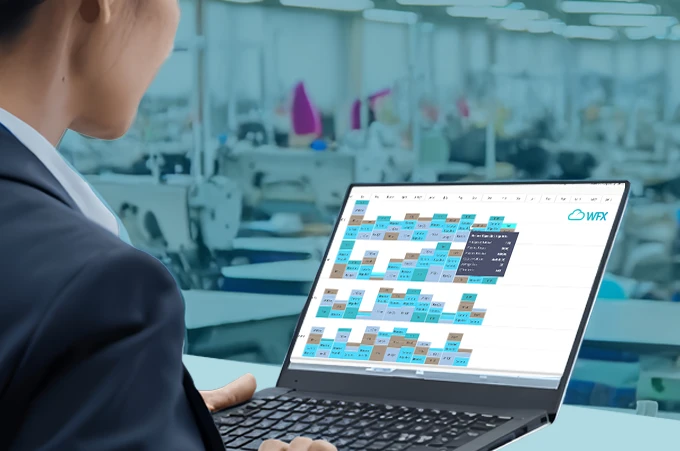

6. Dynamic Production Scheduling Software

Manufacturers have to manage to shift production timelines and priorities for the smooth functioning of the garment businesses. Therefore, the PPC software you opt for should be flexible enough to let you easily adjust production schedules based on changes in priorities, delays, or unforeseen events. Being a key tool in the mass production method and process manufacturing method, the software should enable the manufacturers to remain adaptable and responsive to evolving market demands.

7. Customization & Scalability

Your business needs continuous evolution with progression. So, the software you rely on for production planning and control(PPC) should have the ability to scale across multiple factories or handle larger production volumes. It will ensure that your software continues to support your business without needing major changes or disruptions.

8. Waste & Inventory Management

The software you choose for production planning and control(PPC) should enable you to do precise tracking of raw materials, monitor fabric consumption, manage stock levels, and automate reordering when necessary. It minimizes fabric waste and optimizes resource utilization.

9. User-Friendly Interface & Accessibility

The software you choose for production planning and control(PPC) management should feature an intuitive interface that is easy to operate. You should be able to opt for it with minimal training. Moreover, it should provide cloud-based access and mobile compatibility, giving you the flexibility to monitor and manage production processes from anywhere.